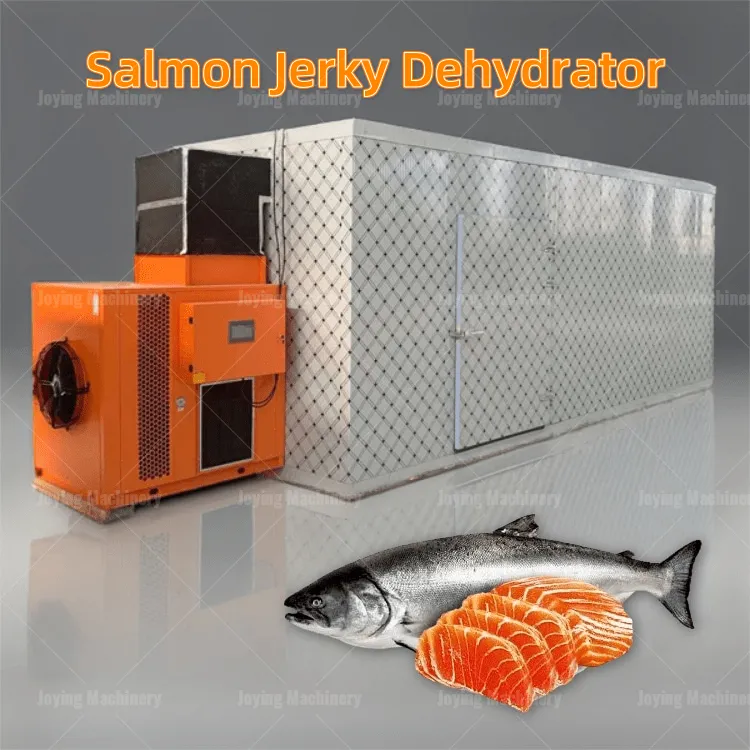

There are many models of salmon drying dehydrators to choose from. The commonly used ones are 12m³, 15m³ and 20m³. If you don’t know how to choose, you can contact us for consultation.

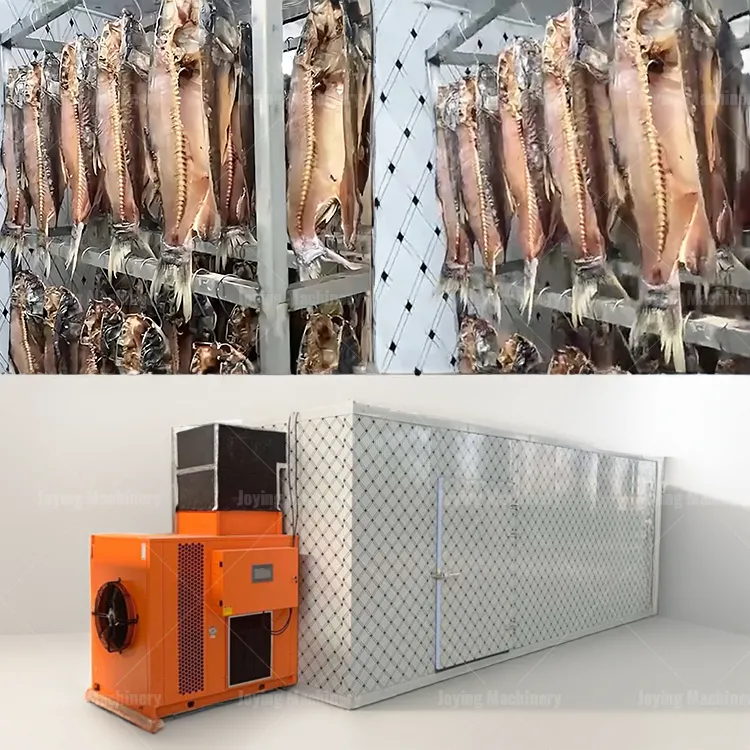

When drying in a conventional drying room, the materials are placed in trays. When making dried salmon, if it is cut into sections for drying, you can use a tray to hold it. If the sections are very large, you need to hang the salmon meat. After drying, the rack and trolley need to be customized.

Dried salmon production requires some special auxiliary equipment, such as: multi-functional fish scale removal machine, fish meat cutting machine, dried salmon dehydration machine and dried salmon finished product packaging machine

Salmon is a fish with high edible value. It is delicious and has elastic meat. It is not only rich in protein, trace elements and unsaturated fatty acids, but also has the functions of replenishing blood, lowering blood pressure, smoothing skin, and enhancing brain function. This is why salmon has always been popular among the public. In addition to frozen fresh fish fillets, salmon is also available in the market as dried salmon. Next, we will introduce the dried salmon dehydrator through the dried salmon market analysis and production process.

Dried salmon, as the name suggests, is dehydrated salmon fillet. Because dried salmon not only retains more than 90% of its nutrients, but also extends its shelf life, salmon can be included in almost all households. Therefore, dried salmon is becoming more and more popular among people and has become an indispensable part of healthy diet.

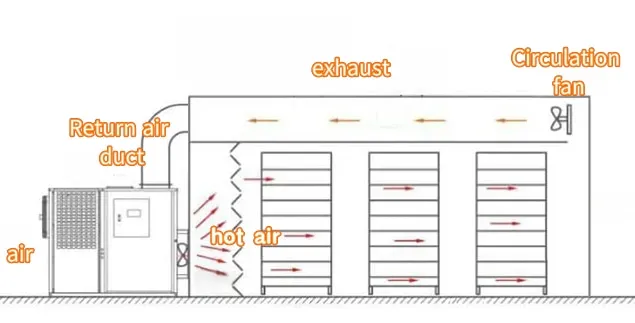

Although the process of making dried salmon is relatively complicated, many steps can be replaced by machines, so it is relatively easy to make. The main step that determines the quality of dried salmon is the dehydration of salmon. Through the following process, we will introduce in detail the relevant steps and how to improve the quality of dried salmon.

In the above steps, we must pay attention to personnel safety and check whether all personnel have evacuated before closing the drying room door. After the dehydration process is completed, our control system will automatically stop heating and extract the hot air from the drying room before prompting that the dehydration process is complete. This ensures that staff will avoid being burned by high temperatures after opening the door and entering.

The dried salmon produced by the dried salmon dehydrator produced by our factory has a high dehydration rate, rich nutrition and better taste, which can fully meet people's demand for higher quality dried salmon.